Challenge

The customer was using a competitor’s vision system with 6 FlexPicker robots on 3 conveyors to pick sausages, but the system was not meeting their satisfaction. There were problems with accuracy, speed, and rotation of picks, and sausages were sometimes being destroyed. The system also struggled when there were many sausages on the conveyor belt.

Solution

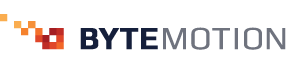

We replaced the cameras with Nano 2020 cameras and trained an AI model to detect and identify different types of sausages. The AI model also provided the correct rotation of the picks in 360 degrees, resulting in more accurate and efficient sausage picking.

Detecting sausages using AI

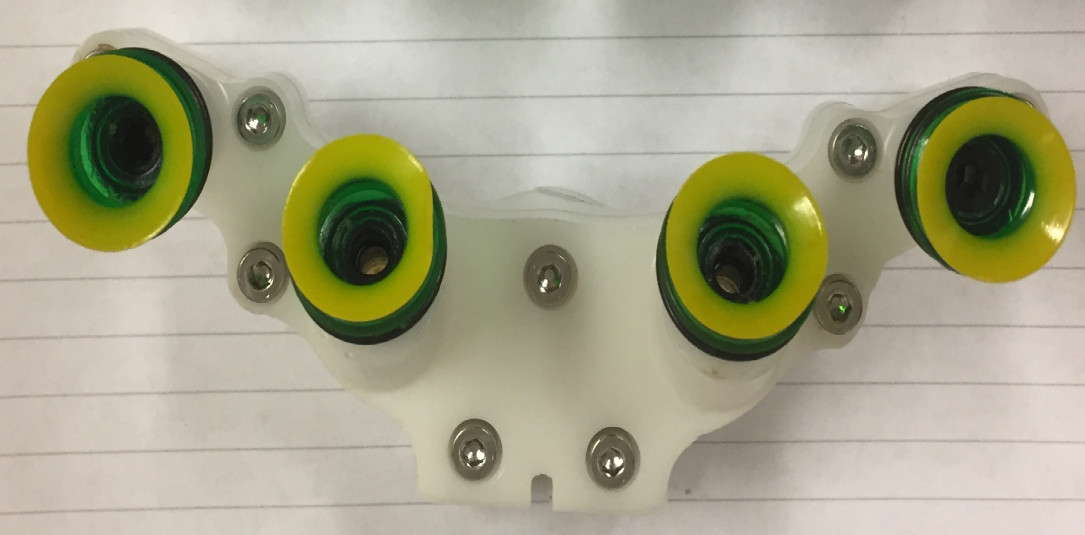

We further enhanced the solution by designing a custom gripper specifically tailored to the shape of sausages. This gripper makes use of the correct rotation provided by the Vision System for each pick. As a result, we were able to achieve a significant increase in speed, accuracy, and successful picks, meeting the customer’s expectations.

6 x ABB IRB 360 Robots

Sausage gripper