Viewer discretion is advised!

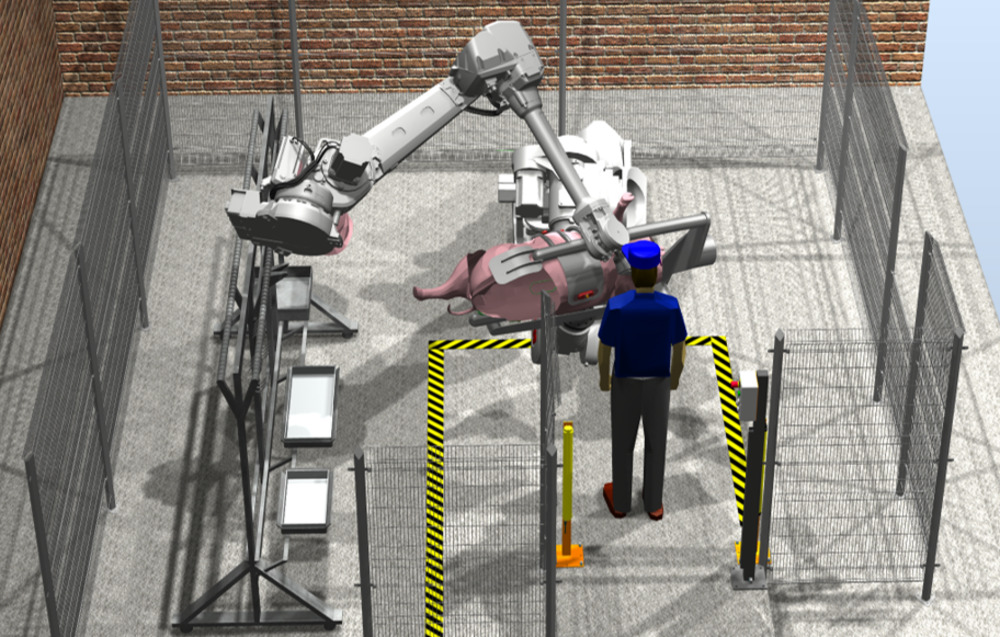

The RoBUTCHER concept enables an autonomous meat factory cell. The main emphasis of the project is research into AI and cognitive systems, which will provide the necessary understanding for the cell to interact with the carcass through physical tasks like cutting, grasping and lifting.

Research Work - Meat Factory Cell

RoBUTCHER is a project funded by the European Union that aims to replace conventional line production in abattoirs with parallel production in autonomous “meat factory cells” containing robots that can lift, hold, cut, and debone carcasses. The meat factory cells utilize intelligent systems to increase the capabilities of robots to perform more complex and varied operations, and offer robustness against equipment failure, scalability to different production volumes, and flexibility to adjust to demand.

Replacing the conventional line with a meat factory cell can improve the working environment, yield, and hygiene. The robotic system will use a combination of detailed computed tomography (CT) data, real-time 3D imagery, and human-expert cutting data for neural network training toward cutting trajectory planning. The RoBUTCHER concept aims to make automation more cost-effective for smaller meat producers.

Two robots woking together, one holding and bending the leg while another one is cutting

Meat Factory Cell (MFC) 3D model

Co-funded by the Horizon 2020 programme of the European Union under grant agreement No 871631

For more information, visit Robutchers official homepage