For one of the largest vegetable production companies in Norway. The company produces open field and greenhouse grown vegetables. The main crops cultivated in the greenhouses are tomatoes (many different varieties), cucumbers and sweet snack peppers and chili pepper.

Challange

Currently, there is no available solution in the market that can effectively inspect piccolo tomatoes for various attributes such as ripeness, cracks, weight measurement, pruning, and packaging. These tasks are considered too challenging for machines, and therefore, the customer relies on human labor for these operations.

Solution

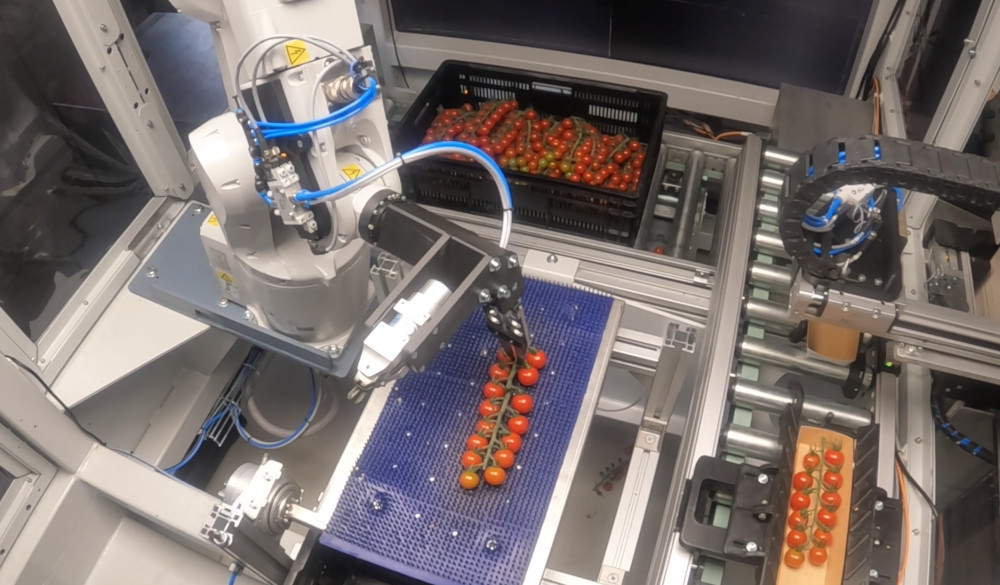

The cell is equipped with an ABB IRB 1200 robot, two Zivid™ 3D cameras, and two Genie Nano™ 2D cameras, as well as a conveyor, sensors, and other industrial equipment. It processes crates of freshly harvested tomatoes from a greenhouse, controlling the IRB 1200 robot to pick the tomatoes from the crate while avoiding collisions with stems or branches.

Inside the Station

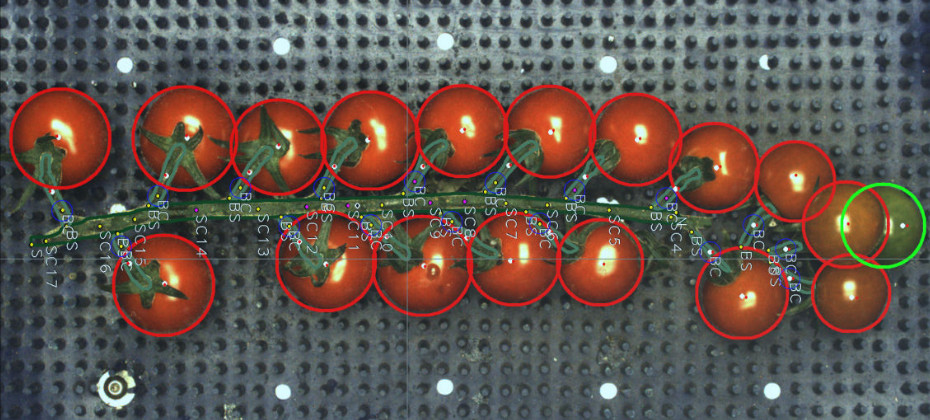

After scanning for cracks using a 2D Nano™ camera, the tomatoes are placed on a cutting table for further inspection. Using AI, a model is trained to detect all parts of the tomato bunch and create pruning and packaging plans for the robot, which is equipped with a custom-designed multi-gripper capable of cutting and packaging.

AI deteticting possible cutting points, estimating ripeness and weight etc.

The system also prunes away any damaged or underripe tomatoes to ensure the correct packaging weight. If any tomatoes cannot be handled by the system, they are sent out for manual handling. Real-time production data is collected, including the number of trays produced and the amount sent for manual handling.

AI detecting pissible stems to pick and proposing the least risky pick position